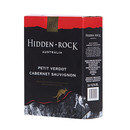

Bag in Box

Ideal for packaging a non-carbonated liquid filling such as wine, bag in box is exactly as it sounds: a corrugated board box with a bag inside. The cardboard box exterior protects the contents from damage and exposure to light, and doubles as an advertising medium.

To make dispensing easy, the bag in box also has a built-in tap. Filling the inner bags with wine or other liquid is done under vacuum, so that as the filling is dispensed the bags contract and the remaining wine or liquid doesn’t come into contact with air. This airtight seal keeps the contents fresh for far longer than a rigid container.