Quality Tests

We test packaging and displays according to statutory and company-specific requirements in the STI Group in-house laboratory. We also work in collaboration with external institutes.

Tests range from shock tests, vibration tests and drop tests, to exhaustive environmental chamber tests. All our findings are fed into our design and development process.

Even products that have never been damaged in transit have their structural designs tested in our lab; this can help to highlight product packaging that may be oversized, for example, with the potential for savings.

STI Group Quality Assurance

Optimisation and testing is carried out at every stage of the entire value chain: from filling and internal logistics, to international distribution and delivery to the end consumer. Only testing shows if a product meets requirements and can withstand relevant loads. An overview of the most important tests:

Overview of Test Procedures

Only testing shows if a product meets requirements and can withstand relevant loads.

An overview of the most important tests:

Horizontal Shock Test

Horizontal forces can be generated by the side-to-side motion of trains, the back-and-forth motion of a truck braking hard, and forklift handling. These forces are simulated using a special test rig

Vertical shock Test / Drop test

This measures the impact of forces on a product dropped from different heights and at different angles. Passing this test is essential for dangerous goods packaging.

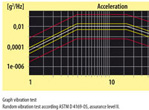

Vibration Test

Vibrations during transport can damage the product as well as its packaging. Test options range from static vibration to random vibration conditions.

Compression Test

This is a quasi-static test that helps test the resistance of a package to compression, and therefore how well it protects its contents.

Edge Crush Test

This test evaluates the edge crush resistance of packaging materials. This is the maximum pressure a rectangular sample offers vs. a vertically applied force until the flutes collapse.

Bursting Strength

This tests the resistance of a circular sample of packaging material (held under tension) to uniformly increasing pressure on one side, until it bursts.

Flat Crush Strength

Designed to measure the flat crush resistance of corrugated board; the maximum pressure that can be applied perpendicularly to the surface of sample material until it collapses.

Puncture Resistance

This tests the resistance of a clamped packaging material sample to penetration by a probe. The force applied is used up in piercing, tearing and bending the sample.

Cobb Test

Cobb testing measures the water absorbency of a paper, cardboard or corrugated board. The Cobb value is the mass of water absorbed in a specific time by 1m² of sample material, under specified test conditions. The higher the Cobb value, the more quickly the material absorbs water.

Environmental Chamber Test

A specially designed environmental chamber assesses the effects of extreme temperature (from -35 to +70°C) and humidity (from 40 to 95%) on samples. This is especially important for sea freight and for delivery to countries with tropical climates.